Biffa sits down with leading high street retail brands to talk waste. Here’s what we learned.

By Julia Turnbull – Biffa Head of Corporate Accounts, Food Retail and Superstores

What do JD Sports, John Lewis, Next, and Coop all have in common? Apart from they are leading high street brands, they all attended the Biffa retail engagement day hosted by Company Shop Group! In a climate where businesses are increasingly held accountable for their environmental footprint, waste management and circular economy strategies are no longer fringe concerns — they’re core to future-proofing retail.

That’s why we brought together major players from across the UK’s food and retail sector, and the event was about much more than swapping business cards - it was about sharing what works, what doesn’t, and where the sector can (and must) go next.

Here are five key takeaways from a day where ambition met reality — no greenwashing allowed.

1. Preventing waste before it happens

One of the central topics of the day was food surplus and redistribution. According to WRAP, simply disposing of food waste isn’t enough, we must firstly aim to prevent waste from occurring, and then secondly recover as much social or environmental value from food surplus as possible, including through redistribution. With over 10.7 million tonnes of food surplus annually, with over 60% still edible and nearly 10 million people in the UK living in food poverty.

Biffa through its partner Company Shop Group redistributed 46,000 tonnes of surplus food and products in 2024. This redistribution effort generated the equivalent of 11,000,000 meals from surplus stock in the last year alone: the equivalent of feeding the whole of the UK 1.6 times. We work with leading retailers and manufacturers to stop waste before it happens and unlock financial, social and environmental value for our partners.

For food that is no longer suitable for human consumption, the UK’s Food and Drink Materials Hierarchy is guiding the UK value chain towards a more sustainable food system. Retailers like Waitrose are exploring solutions that move the management of food waste and surplus higher up the hierarchy deeper integration into the waste hierarchy. This includes investigating the development of more nascent solutions like the use of black soldier fly larvae for processing food waste and transforming the outputs into a high-protein feed that can be used in the food supply chain - aiming to provide a closed-loop solution for the industry.

2. Design for recyclability is essential

The group was united in their belief that it is crucial going forward that products and packaging should be designed for recyclability and with as much recycled content as is possible. A standout example was the company ReBorn, which utilises 100% recycled plastic packaging from Biffa and transforms it into stylish home, office and bathroom products. All products are manufactured locally in the UK, minimising the environmental footprint of the products and supporting the economy.

Initially launched exclusively in John Lewis in 2023, the brand is now selling in eight other national chains and targeting many more in the next year. ReBorn's success isn’t just about ethics — it makes commercial sense too. Reborn is a prime example for how sustainability and circularity do not have to be at the expense of profits.

3. Textile recycling is the next frontier — but we’re light years behind

While food waste and packaging are a core focus for retail, the issue with textile waste looms large across all sectors. The UK throws away over 330,000 tonnes of clothing each year - much of it going to landfill or incineration. Retailers during the session were vocal about the lack of infrastructure, particularly compared to their European counterparts.

Project Re:claim, is a joint venture between the UK’s largest charity textile collector, The Salvation Army, and leading circularity specialists Project Plan B.

This venture is working on the development of a polyester recycling solution, with a plant opening in January 2024.

The Salvation Army joined us for the day to showcase its progress toward turning discarded garments into usable materials again. While many early-stage fibre to fibre recycling solutions are in development and presenting the potential for future recycling opportunities, there are still substantial challenges with the supporting infrastructure as well as a lack of a design for recyclability in textiles upstream.

The takeaway was sobering. Most so-called redistributable textiles are still currently shipped to countries on the possibility of being reused. However, a large proportion unfortunately become waste, and where there is a lack of waste management infrastructure, this waste ends up in landfill. Genuine end-of-life recycling is rare, expensive, and under-regulated.

Calls for reform focused on Extended Producer Responsibility (EPR) schemes for textiles. Without clear demand and fiscal measures, the investment in the technology and infrastructure to develop a market for secondary materials is a long way, however a producer pays approach could begin a process of change.

For more information

4. Policy momentum is building - and it's supporting progress

Significant policy changes are on the horizon, presenting both immediate challenges and substantial opportunities to enhance circularity within the retail sector. While adapting to these changes may prove difficult in the short term, they create pathways for meaningful progress.

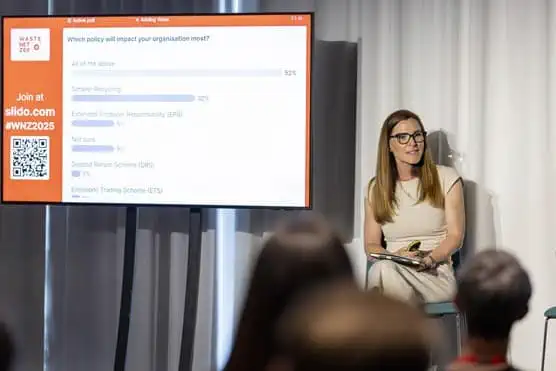

Two policy initiatives stand out as important for the sector: the implementation of Simpler Recycling and the introduction of Extended Producer Responsibility (EPR) fees.

Simpler Recycling will establish more consistent collection systems across businesses and local authorities throughout the UK over the coming years, significantly improving recycling rates. However, the policy's inclusion of Liquid Paperboard Cartons (LPB) in collections, while well-intentioned, may create unintended consequences. The reality is that these materials face a challenging journey to processing, with only one facility in the UK fully dedicated to handling them.

The dairy industry has demonstrated what's possible through supply chain collaboration. Working in partnership with Biffa Polymers and the retail sector, they've created a closed-loop system that now features 100% recyclable HDPE containers for dairy milk. This standardised format offers a proven model that we encourage wherever possible for dairy milk bottles.

More generally, EPR fees will incentivise the shift toward more recyclable packaging formats while supporting innovative start-ups working to create and scale potentially more recyclable, circular alternatives to traditional LPB cartons.

Several participants noted that consistent national policy and more guarantees that EPR fees will be spent on appropriate infrastructure - particularly around recycling - would help retailers invest with confidence, and consumers would be more likely to change behaviour if they saw clear, consistent systems that work.

5. Collaboration isn’t a nice-to-have — it’s a competitive advantage

One of the most powerful aspects of the day wasn’t a specific technology or policy — it was what happened in the margins.

Aligning with customers and suppliers, as well as their operations, values and goals, is essential for addressing the challenges within the industry. Building strong relationships boosts efficiency and paves the way for innovative solutions, such as tackling issues from food waste and packaging to consumer behaviour and waste segregation – such as the example of HDPE milk bottles mentioned previously.

The key takeaway: collaboration on waste management and circularity strengthens the entire industry - a rising tide truly lifts all boats.

Final thoughts: from talk to action

The retail sector doesn’t lack ambition. What it lacks is a unified framework that rewards action, supports innovation, and encourages shared responsibility across supply chains. The conversations we hosted weren’t academic — they were grounded in daily operations, real-world trials, and a common desire to move forward faster.

Retailers understand that waste is no longer just a cost — it’s an opportunity. An opportunity to reduce environmental harm, cut operational inefficiencies, engage more meaningfully with customers, and unlock new value streams.

As one participant put it: “It’s not just about being circular. It’s about being smarter, together.”